Fast Tracks Turnouts

Well, here's the first attempt.

Needless to say, I was very pleased. This is a code 83, HO, number 6. I know Tim has better videos, but I couldn't resist giving it a whirl.

I'm new to soldering as well as to the hobby, so I think it's a testament to the Fast Tracks products, as well as their excellent videos and references that this turnout works as well as it does on my first try. For those interested, it took me about an hour and half to assemble this turnout.

The only problem I've run into so far is that the turnout ties I ordered from Fast Tracks are a bit thicker than the ones from Micro Engineering, and they don't match either the copper cross ties or the MEs. I know sanding will take care of that, but there it is.

I have a question for anyone who has or has made this (or Tim, if he notices this post). Is is a bad idea to use different rail sizes in the same switch?

Let me explain. I'd like to make a single crossover, from the main (code 83) to a Siding (code 70). if i mix codes, especially at the frog point, will this cause performance issues, or am I better off starting the smaller rail after the turnout?

Here's an illustration to show what I mean about which code to go where.

>> Posts index

Navigation

Journals/Blogs

Recent Blog posts:

Comments

What you show is not prototypical

Scarpia:

That's not how the prototype would change rail codes, so what you show is not prototypical.

The prototype uses the same rail code throughout a turnout, and then transitions between rail codes well past the frog. It is incorrect to have one rail be higher than the other as you show. Both rails must always be the same code.

The prototype would likely change codes and do the transition roughly halfway through the crossover about where you have your vertical line and the changeover would happen at the same place in *both* rails (be perpendicular to the direction of the rails).

Joe Fugate

Publisher, Model Railroad Hobbyist magazine

Read my blog

Very Nicely Done!

Hi,

Great work! Its always good to see the results modelers are getting with our tools. Thanks for taking the time to post a video, I think this is the first time I have seen anyone show some video of the trackwork they have built using the tools (correct me if I'm wrong). Of course, Joe is the first MR forum that I am aware of (other than our Fast Tracks forum) that has video embedding turned on.

If using individual wood ties (I think that is what you are referring to) they may be slightly thicker than some commercial track products, but that isn't necessarily an issue. Once the wood ties are glued in place on the roadbed it is always good practice to sand them flat prior to installing trackwork, this will ensure a smooth surface and keep everything on the same plane.

When using our laser cut QuickSticks, these are glued to the trackwork first, then installed onto the roadbed in a manner similar to commercial RTR turnouts, therefore sanding isn't necessary. The material we use for our laser cut ties is the same thickness as commercial track and will match up well.

Joe is right about the crossover. The prototype would likely switch rail codes in the middle of the track between the two turnouts using transition joiners to keep the top of the rails in line with each other.

Another option would be to build the entire crossover from one size rail, and use transition joiners to connect the track leading into the turnouts. This would likely provide the most reliable operation and is what I would suggest.

Cheers!

Tim Warris, Fast Tracks

http://www.fast-tracks.net

Follow us on Twitter for news, updates, special offers

and discounts only available in our tweets.

http://www.twitter.com/

Excellent, Scarpia!

I've got my basket filled up on the Fast Tracks site, I'm just waiting for enough money from my "allowance" (the wife and I each have an allotment for our hobbies in the budget) and then I'll be ordering them. I, too, haven't done much soldering, but I watched all of Tim's videos on his site and I think I can do it. He makes it look pretty easy and he has everything he uses available on his site. I've seen a lot of "how-to's" that never tell you exactly what you need or where to buy it and you are left to hope you get the right thing. I looked and looked around town for a fine tipped soldering iron, but not one could I find, so I'm glad Fast Tracks has them available. I also credit Joe with his video series - he almost always shows you a website and the product to get the stuff he's showing you, or tell you what store you can commonly find the item.

And I expected to screw up the first two or three I do, but seeing you did such a great job on the very first one, maybe there is hope? Keep posting your pictures.

Dave

Building a TOMA HO Scale '70s/80s era

GMT-6

I have the #6 switch for N

I have the #6 switch jig for N scale and I have to say that I love it. I have built 4 switches so far and each is as smooth as glass when routing through them. My next step is probably to get some of the tie racks so that I can hand lay the track between these great switches (either that or get the #4 switch jig so I can build the yard module).

The discussion of rail code connections comes at a great time as I am using code 55 for the main and code 40 for the sidings and yards. I would agree that the best place to transition the rail would be where the dashed line in your diagram is drawn.

Does anyone know of a source for long wooden rail ties in N? As you can see from the diagram, having some nice long pieces would surely help.

-----------------------------------------------------------------------------------------

N scale, DCC-NCE, Switching, Operations

I think...

that FastTracks has them, but perhaps you've checked that already. I know they have the wooden rail ties, but perhaps they don't have the long ones.

Dave

Building a TOMA HO Scale '70s/80s era

GMT-6

Fast Traks sells both longer

Fast Traks sells both longer "switch" ties and regular cross-ties. I have found only one company that sold long strips of tie material: http://www.kapplerusa.com/y2k/p-value.htm#n_bulk-ties. Oddly, I ran the numbers and it seemed the bulk material was more expensive then the 1000 ct tie bags per foot. Northeast Scale Lumber may also (http://www.northeasternscalelumber.com/), I have not been there in a while to look. I have not ordered from either of the latter two companies, I don't know how the buying experience would be.

I have seen a few places that offer both scale 8' and 8'6" ties.. when would I use one over the other?

Chris

“If you carry your childhood with you, you never become older.” My modest progress Blog

Depends on your prototype

Chris:

8' or 8'-6" ties depends on what your prototype used. If you're freelancing, then pick something. If you're proto-freelancing (basing your freelancing on certain prototypes), then again, check what you're reference prototype used.

Joe Fugate

Publisher, Model Railroad Hobbyist magazine

Read my blog

Thanks, I will do some

Thanks, I will do some research. I wasn't sure if it was an issue of location.. bogginess of ground or some such.. or just a prototype preference.

Chris

“If you carry your childhood with you, you never become older.” My modest progress Blog

Transition

Ok, so it's not-prototypical, and probably will be bad as far as operations, thanks for that. I know Sometimes in this hobby it's easy to find information on what locomotive ran when, but very difficult to find the smaller details.

I could join two turnouts with transition joiners, but I want to make a very tight cross over, and not have joiners in place at all (the same rail running from each frog across). So it sounds like having it transition to lighter rail after the cross over is the way to go.

Too bad no one makes transitional rail, like I've seen in full scale.

Per the ties, I wonder if the ME ones I got from another source were the low profile, I know I can sand them, and will, but it was a surprise to me.

Tim, I'm not joining to any commercial track, at all, and even the loose ties i got with you are taller (1/16" of an inch maybe?) than the quicksticks, of which I have a set, and the pc ties. I'll check the bag, maybe I got the wrong size?

I do have all of the forms, I have the #5 and #6 point form, and I just got the stockaid, and like them very much. I know this can all be done by hand and experience eye without them, but it alleviates a lot of stress for the new modeler to have the forms in hand, especially as they work.

I'm not going to lie, I wish they were a bit less expensive, (I also wish that beer was free, but there you have it) but the products are very well crafted, so the value is certainly there. I do worry a little about them rusting in my humid basement. Hopefully I'll be busy enough with them for that to not be the case, although I may store them wrapped in a piece of paper towel sprayed with WD-40.

I also picked up the rail bender (from the eBay purchase), and I'm excited to use that one. I'm also tempted to simply get the regular templates for straight and curved track, but I haven't looked at how things like easements work yet with those jigs.

One thing I really like about the jigs is the flexibility. I like the fact that I can cut down the turnout much tighter to the frog and points; this seems like a great way to save valuable layout space without loosing functionality. I also like the idea that even if I totally mess up one, I'm only out a few dollars in materials, as opposed to $15 or so for a good brand. And I have to admit, I think the "open" frog looks great, and is certainly smooth running.

I appreciate everyone's comments. Last night's success was very exciting for me, and I'm looking forward to generating turnouts by the thousands! Tonight, however, I need to check and make sure I didn't screw up the electrical breaks, and hook some wiring up to it.

Can you tell that I'm having fun yet?

I tested it last night for electrical contact, and after a half hour of chasing ghosts, I was able to run a DC loco over it with no problems. I had gapped correctly, but there were transient strings of copper on the edges of the PC ties that were shorting it out.

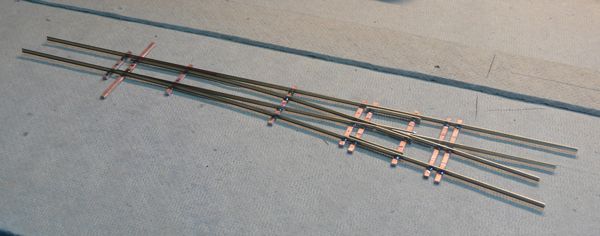

With that under my belt, I dove right into the hoopla. I decided I wanted a crossover, and not just two turnouts layed back to back, but one that had a solid piece of rail from the diverging stock rail to the opposing frog.

So, nothing like going into the deep end right away. And just 3 hours later....

The completed cross over

Here it is with the previous standard turnout for size comparison

I have put it on top of the Fast Tracks quick sticks ties for this turnout to show it's compressed size.

One of the huge advantages of the Fast Tracks system is you can really compress complicated track work. Here is how I've originally planned the entrance to the yard

And here shows how tight you can move the switches, gaining (in this case) a couple of inches on the far end.

So how does it work? See for your self!