Lighting

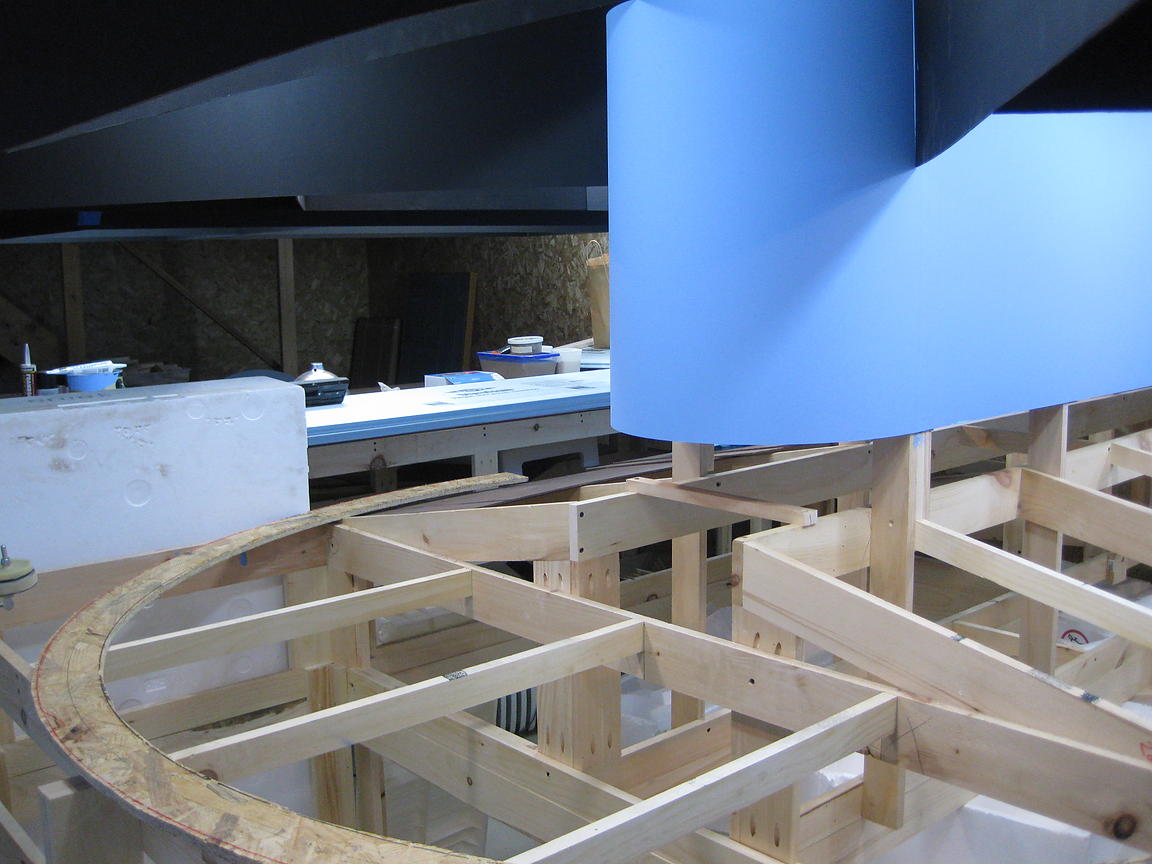

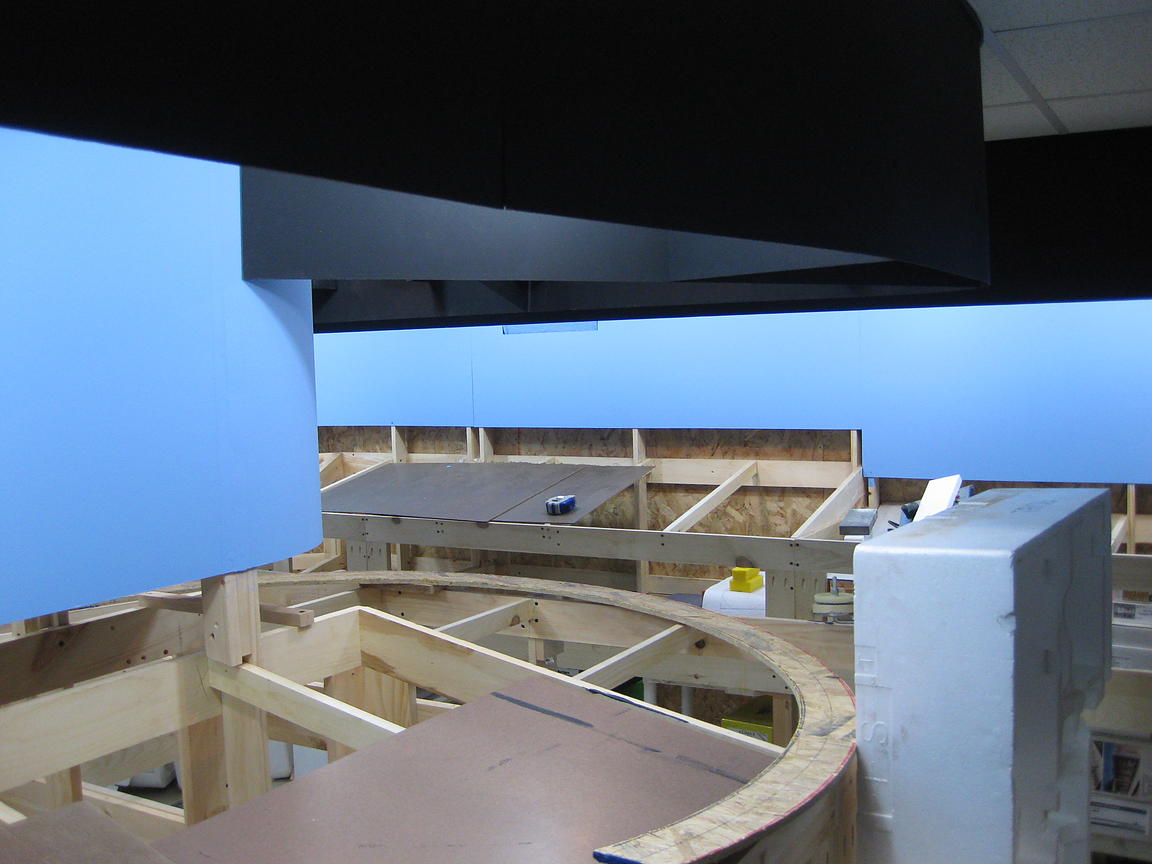

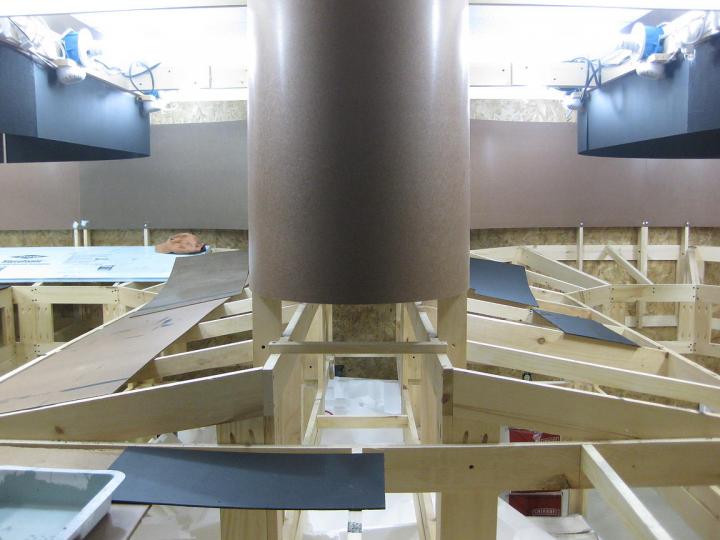

I am in the process of re-building a layout to replace the one I lost when my house burned down. I wanted to have a shadowbox effect to an around the walls layout with a center peninsula sticking out. We used CFL 6,000K bulbs in conjunction with Halogen under counter lights for warmth. They Halogens dim for dusk to dark effect. We noticed a problem when we were partway done around the peninsula that I have read others having-you could see the lights inside the valance on the peninsula when standing along it's edge. The valance couldn't come down any further as it would block the scene and make working on the layout very uncomfortable. We came up with the idea for baffles painted flat black as a block for seeing the lights. It seems to work very well except for short people. I guess I'll get them a box to stand on!! Pictures are attached which should be self explanatory. When I get some time, I will start a blog about the layout and it's progress.

Peter

Here's a few shots of the portability of the modules.

Moderator edit: changed the images from attachment to inline.

>> Posts index

Navigation

Journals/Blogs

Recent Blog posts:

looks like a nice solution

I kinda like how your benchwork angles upwards in the back as well... I am curious though, why did you choose to do the benchwork at a slight angle rather than flat like most others do?

Mike

I like your use of Kreg jig...

...not so sure about using chipboard for roadbed. That stuff doesn't lend itself well to structural integrity unless kept in relative temp and humidity levels. As for the sloping supports I think it's a neat idea and may copy. As long as the roadbed is kept level the rise in the background would actually help with adding scenery details.

John

modeling CMStP&P from late '40's to '60's

Lighting

I agree with John about not using chip board for the sub-roadbed. I'd use 1/2" plywood for the sub-roadbed. I'm also curious about why the benchwork was built on an upward angle. I had enough trouble keeping my benchwork level when I was building it, but then I was building a flat top benchwork on which I was going to install 1/2" plywood with 2" foam board glue on top of it.

I have a similar lighting arrangement on my layout. I used David Barrow's method of using single tube fluorescent strip lights directly behind a 12" valance. There are some places at the end of a peninsula and at the end of some of the aisles where you can see the fluorescent lights if you look up. I don't think this will be a problem when the trains are operating since people's attention will be focused on the trains.

Bob

Sloped benchwork.

My original thought was in a shadowbox type display, the back should be higher than the front for perspective. We built all the straight 30" by 72" module sections first with the slope. Had we built the corners first (those were a real bear with all the angles-luckily my father and son helpers are carpenters by trade!) we probably would have done it all flat and used raised roadbed. It's hard to see, but each section is a stand-alone with the backdrop, valance and lights attached. The modules all have a base and a section could be taken out to work on at a different location by removing a few screws. I did leave the city section and the engine facilities area flat.

The "chipboard" is actually OSB which is used for roofing, flooring, and siding in home building. If you read up on it, it's actually dimensionally stronger than the equivalent size exterior plywood. My pals brought me a sheet to play with and I'm not sure if I like it or not. It has a waxy smell to it. I have only cut that one piece so far and I will make up my mind after I attach it to some risers.

Unfortunately I will have to take some weeks off as I'm having rotator cuff surgery on Monday and will be one handed for a while.

Peter

Couldn't figure out how to attach pics to this so I added a couple to the first post. P

Chipboard

Just picking linguistic nits here, but Oriented Strand Board really ought not be refered to as "chipboard" as that is the name of a paper product here in the US and is a nickname for particle board in Europe. "Flakeboard", maybe?

The waxy smell is because wax and resin are the binding agents used in its manufacture. Peter is correct in noting that its physical properties compare favorably with, and in some aspects exceed, those of plywood.

However, model railroaders should be concerned with the fact that, once cut, OSB is very moisture absorbant along its edges. That red-orange paint we are all familiar with on its edges is there as a sealant for this reason. It swells considerably more than plywood, loses more structural integrety and when it dries out, does not return nearly as well to its original dimensions. This is probably not a concern in terms of humidity, but considering that a lot of scenery techniques involve the introduction of a fair amount of water to the area, we should be careful about when and where it is used.

Considering the cost differences for the amount of materials required to use it as roadbed, I believe I'd give it a pass.

Relinquishing the pulpit,

Dave Stewart

To answer a couple of your questions

OSB is not Moisture absorbent if you buy the correct grade as each piece of,or chip of wood in Exposure 1 Exterior grade is coated in a high performance resin glue that makes it 100% water resistant even when cut into 1 in squares and set in a 55 gallon drum filled with water and then left for a week. When the week is over dump out the wood and let them air dry and there is no sign of any square having soaked up any water what so ever.

Here is a site that explains what OSB is and how it's made.

http://www.askthebuilder.com/304_Plywood_and_OSB_-_Which_One_Is_Better_....

Yes low grade OSB isn't put together exactly the same way and it isn't marked exterior grade but the glue is still a resin type adhesive.

There is a second product that many people think is OSB and it isn't. It is called Particle Board.

http://www.suburtiasa.com.my/index.php?do=annual_report&sub=particleboar...

Particle board is mistaken as OSB and is NOT OSB and it sucks up water like a sponge. Particle board is made of recombined high pressure compressed sawdust and comes in 4X8 sheets like plywood. Particle board is also used to make low cost furniture when coated with a thin coat of wood grain colored vinyl.

Particle board acts much like what Dave was talking about. In full sheets it is water resistant from the Wax that coats it. Once cut you need to seal the edges with a one part premium water proof wood glue like Titebond II to reseal the sheet and keep it water resistant.

I wouldn't recommend using particle board on your RR as Track bed like cookie cutter or used as spline because it doesn't bend or flex. Instead it tends to snap or break very easily Some grades of Particle are called MDF (Medium Density Fiberboard) http://www.chenminggroup.com/Products/MDF/MDFHDF/MDFmedium-density-fiber...

Dan

Rio Grande Dan

Sloped Benchwork

I think the sloped benchwork is a fascinating approach. I have to ask though, and I'm sorry if I missed it, but why any solid under-layment at all?

At first glance, this seems like an idea approach for a spline or cookie cutter roadbed on risers, and foam board terrain. (but I could be missing something!)

sloped benchwork

Scarpia. Not sure I understand your question completely but if you're asking about track roadbed (or let's call it under-roadbed) I have not gotten that far yet. The piece of OBS is just sitting there to help determine the fascia location. There are joists every 12" to which will be attached risers to which will be attached the under-roadbed, then foam, the cork, then track.

To the two gentlemen who took the ime to share their OBS research, thank you, thank you, thank you. This was what I discovered when I looked into it after the sheet arrived, smell and all. Unfortunately I type so slow I'd never get any layout work done if I passed all that along. My concern is exactly that-water from scenery building. I used a lot of colored "washes" on my last layout to color rock out cropings and I love rock outcropings! I probably have every mold ever made so lots of rock!!! As a precation I plan to test scrap OBS with water both sealed in various methods and unsealed and then decide on it. It is cheaper than plywood, but I believe it' a bit heavier. As this is my last layout made to be moved, weight is a factor and cost really should be damned!!

Thanks, more later.

Peter

By the darn way

Kudos to you and your helpers for some really first class work! Your benchwork is superb and your backdrop, lighting and valance (not to change the subject) are no less excellent. This looks like it's going to be one very fine layout.

Good luck with your surgery and the ensuing therapy. Remember that you can still point with the other hand to keep your helpers busy! I guess it'll be about a year before you can start delivering fastballs again!

Dave Stewart

Lights

The only solution that I can offer is to remove all the existing lights and valances and put something suitable for the suspended ceiling you have already, because anything else will be visible at some point. You MAY be able to concoct something using a regular suspended ceiling fixture and the spots (everything out of sight).

_______________________

Long life to Linux The Great!