Hand Laying Track

As part of the next stage of my testing before the big layout build, I want to lay a bunch of track by hand to see how much work it entails, and evaluate it from cost, performance, and appearance standards.

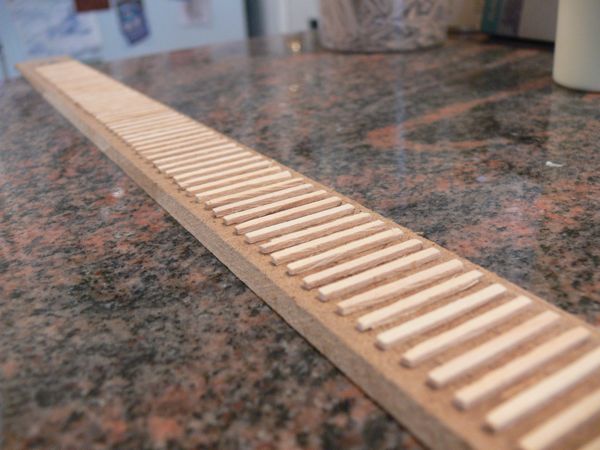

First up though, is a small mini-test section. Here's what I've gotten done so far.

|

Materials/Tools in this picture

|

|

Ties go in the jig. |

|

and a piece of painters blue tape is applied, than the whole thing gets pulled carefully out. |

|

just a little (as you can see) yellow carpenter's glue is applied |

|

And then the ties go down. After the glue had set for an hour, I carefully pulled the tape off. |

|

Ok, this is looking pretty good so far. |

|

Some people recommend dipping the ties in advance, others say to do so after they are glued down. I thought I would try the latter. This picture shows some of the ties after just one coat of the Minwax stain. Materials added:

|

So I'm not satisfied with the tie color, I think it's too black.

I removed one tie to show myself where the "break" is - the first set I'm leaving untouched, the second set I want to drybrush brown over.

The next set of ties will be stained with a black/brown mix. I want a bunch of sections to determine what looks best.

>> Posts index

Navigation

Journals/Blogs

Recent Blog posts:

Comments

The track nails are the Micro

The track nails are the Micro engineering medium; I have some small ones on order. I have run a truck successfully over the segment, and there is a little bounce over a couple of the nails.

Thanks!

Looks good! I think you found

Looks good! I think you found a good color.

I think that color would need to be faded for older track, but the base tone is good.

I have been planning to build a simlar tie jig out of styrene as I have seen done in a few hand laying articles, such as this one (http://coxy.squarespace.com/coxys-n-scale-and-railroad-bl/2006/12/24/n-scale-tie-strip-jig.html). The fast tracks definitely seems an easy way to go. I will probably still try to build one and if it becomes a complete fiasco go ahead and order at least the mainline jig.

I am still not sure how the workflow will go for non-turnout track in N where the track is attached by soldering to PCB. The height of the PCB is slightly different then the height of the ties so laying it out ahead like Scarpia did seems problematic. However, I know this is how the San Diego Society of N Scale do it for their code 40 track, so their must be a way. I would love to get a chance to see their process in a video. I guess I can either glue a shim to the bottom of my PC tie or find a thinner tie material.

Anyway.. looks great.. I envy HO for being able to spike the track.

Chris

“If you carry your childhood with you, you never become older.” My modest progress Blog

Weathering

Next up is to hit it with Joe's weathering powders, that's a step I haven't done yet. I'm hoping that will "age" the ties a bit.

It was nice to meet you at the show, yesterday, Chris! I hope your kids were able to finally enjoy the Lego Layout.

Likewise, I am looking

Likewise, I am looking forward to getting my flocker put together and to try out the flock material you gave me! I wasn't expecting quite so much.. a lifetime supply! I will pass some of it on to some of the other N-scalers in the area to try too.

Something about the Lego layout disturbed my toddler.. maybe it was just to fast and frantic. The trains were moving at very high speed and taking very sharp corners. He loved the G scale layout on the stage almost as much as he loved playing with the provided step stool.

Chris

“If you carry your childhood with you, you never become older.” My modest progress Blog

If you need shim material,

If you need shim material, your local sign/plastics dealer can get you a 4x8 sheet of .020 or .060 styrene for about 25 bucks.

---------------------------------------------------------------------------------------------------------

Benny's Index or Somewhere Chasing Rabbits

Tie colour

Sorry for being so slack in replying, but I forgot about this string.

The Raven Oil is manufactured in Aus, however Tandy Leather in the USA would act the same because leather colourings are designed to suck into the grains of the leather and will go almost all of the way through. They all are oil based to carry the colour.

I am looking through my files to see if I still have the protos of the On30 layout that I built some years ago. I still use the recipie on my hand made HO trackwork now.

The colour is a little washed out but you can see how it allows the grain to show through.

The timber is all home cut redwood on a bandsaw to give the rough cut look of the early times.

no worries

Thanks, Tom, and no worries. I've migrated to paint instead of stain, based on Tim Warris' suggestion on how to disguise the PC board ties of the turnouts. I'm still making notes though for the future, as I may try mixing and matching down the road.

I use paint

I just use diluted black Acrylic paint for "staining" ties. It looks fine. Most ties are creosoted blacker than coal to start with and then fade to grey. The little bit of brown effect is achieved by the yellow of the wood showing through slightly.

Jurgen

HO Deutsche Bundesbahn circa 1970

Visit the HO Sudbury Division at http://sudburydivision.ca/

The preceding message may not conform to NMRA recommended practices.