Electrofrog =/= work same way (as an Insulfrog)

Dear Dave, MC,

Um, I fear that MC may not be 100% correct about the "electro-frogs work the same way (as Insulfrogs)",

and this could be the root of your confusion Dave.

In direct answer to the question, PECO turnouts "internally switch the frog polarity" by simple means of which switchrail is making contact with it's adjacent stock rail, (IE the way the turnout is thrown automatically "switches the frog polarity").

Firstly, we all get that Electrofrogs are all-metal all the way thru the frog, with both switchrails + frog + both closure-rails + both diverging-rails effectively "electrical bonded together" into one assembly,

and that Insulfrogs use plastic frogs, with the straight/curved switchrails and associated straight/curved-route closure-rails + diverging-rails not "electrically bonded together", yes?

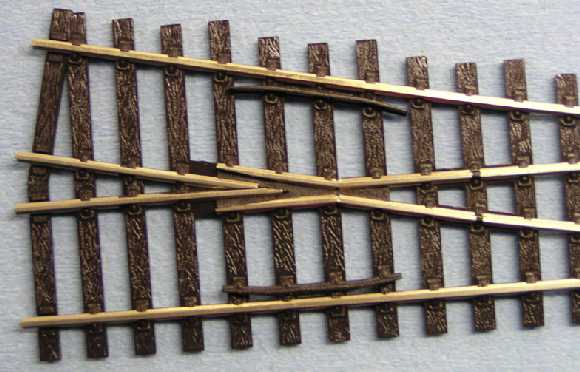

OK, with that in mind, let's look closely at a PECO Electro-frog:

NOTE the little black plastic "insulating" tabs 4 sleepers to the LEFT of the frog point/tip!!!

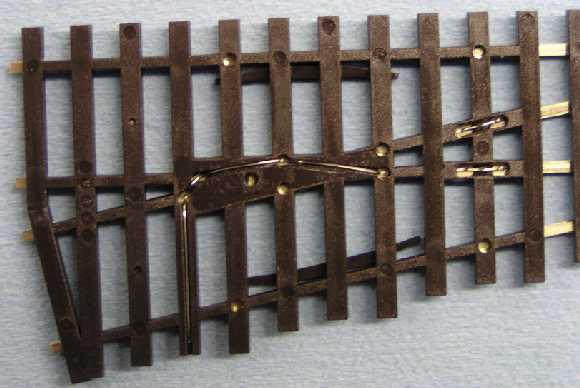

If we flip the turnout over, we'll see that "ex factory" these built-in "closure rail <> frog insulating gaps" are jumpered with short little wires.

(check the 2nd sleeper in from the Right of the pic)

Now, with the links in place as shown (ex factory), the power path is

stockrail> switchrail> closure rail> frog

(and back down the other closure/switchrail, as well as to both Diverging rails)

The benefit is that there is no immediate need to "power the frog" from an Aux switch/Juicer of any description,

the "switchrail in contact" will pass power automatically, and the mechanical over-centre spring will "snap" the switchrail hard in contact with the stockrail, thus ensuring good contact under most conditions

NOTE! This PECO factory-stock config also creates what is known as a DCC "un-friendly" turnout, as the open switchrail is of the opposite polarity to its adjacent stockrail. This means an excessively-narrow-in-gauge wheelset could glance between the stock and switchrails, causing a momentary short.

Also, adding MC-style jumpers directly to such a factory-stock turnout (IE with those factory-jumpers in position), will immediately create a hard-wired short.

(as all switchrails/closure rails/frog are electrically continuous, and the frog is common to both rails/routes)

IE stockrail> MC-jumper> closure rail> frog> closure rail> MC-jumper> stockrail

If you need to, read thru that again, I'll wait here...

SO, what to do?

- If you elect to leave the PECO jumpers in position as they are ex-factory,

Do Not install MC-style jumpers,

and ensure that all wheelsets are perfectly "at-gauge".

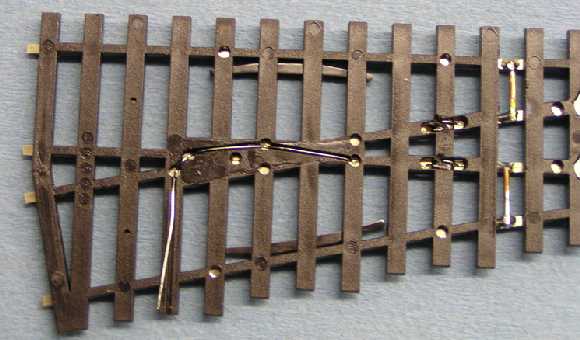

- If however, you wish to modify the PECO Electrofrog turnouts to be "DCC Friendly" a la Alan Gartner's "wiring for DCC" website definition (where the pics above have been greatfully lifted from!),

then you will need to snip those jumpers away "open-circuit". This will allow the plastic insulating "tabs" to do their job, and isolate the switchrail/closure-rail assemblies from each other, _and_ from the frog.

You can then either rely on the built-in over-centre spring to "snap" the switchrails up against their associated stockrails to make contact and feed the switch/closure-rail assemblies

(with the "not thrown" switch/closure-rail assembly becoming electrically dead),

or add MC-style jumpers between the stockrails and associated switch/closure rails.

(It's hard to see, but the jumpers have been snipped-thru to isolate them, with what appears to be a Xuron nipper or similar)

Oh, and _now_ you will need to use the PECO-provided frog wire, and some form of external micro-switch/juicer system, to feed power to the frog.

For a slightly more-lucid breakdown, check the "Wiring for DCC" website directly.

http://www.wiringfordcc.com/switches_peco.htm

In _all_ cases, (whether left "ex factory", or modified "DCC friendly"),

MC is correct that Electrofrog turnouts will need to have insulated joiners (or rail-gaps) on the _heel_ end of the diverging rails from the frog.

I hope this helps...

Happy Modelling,

Aim to Improve,

Prof Klyzlr

PS you can add MC-style jumpers directly to Insulfrog (plastic frog) turnouts,

as the straight and curved switchrail/closure-rail/diverging-rail assemblies are not bonded together via the common metal frog.

In such cases, certainly yes, they very effectively augment the stockrail/switchrail contact with a hardwired path.