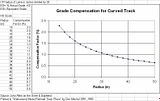

So, is a helix with a 2% grade and a 30" radius equal to a grade of 3.1% on the straight? The magnitude of curved track on pulling power is larger than I have sensed.

Fred W. wrote:

"The equivalent grade for curved track came from John Allen. I have never found any evidence beyond it being Allen's hypothesis for a formula for the extra drag created by curved track. It would have some basis on Allen's experience in HO scale using trucks before the days of RP25 wheels and free-rolling wheel sets. A practical experiment (pure speculation on my part as to Allen's conduct of any supporting experiments) would be to check how many cars a given locomotive can pull up a known straight grade as can compared to how many cars can be pulled around a known radius curve.

"As a photographer, John Allen would likely have been familiar with 1/x type formulae. If his data points gave him a curve that resembled the chart, it would have natural to fit a c/r curve to the data, where c is a constant and r is the radius. Remember that Allen would not have had computers to optimally fit curves to the data.

"And Allen's formula makes sense if one assumes flat treads. With a flat tread, there is a differential in path distance around any curve for the two wheels. This causes wheel slip (hence increased friction), with the friction going up at a non-linear rate as the curve gets sharper.

"Most RP25 treads use the maximum allowable 3 degree taper for ease in manufacturing. The taper means that the wheel set can adjust to curved track without wheel slippage until a certain minimum radius is reached. What that radius is depends on how far into the flange root you will allow the wheel to move to compensate for the unequal path lengths. When I ran the calculations, I found you typically you moved into wheel slip around a 20" radius in HO. Exact track gauge, wheel gauge, and how much use of the flange root you allow all affect the final value a couple of percent.

"Bottom line: my theory is that with modern tapered wheel sets and decent flange root radius, there is very little extra friction on curves until around the 20-26" radius point (in HO). At that point there would be almost a knee in the curve, with significant increases in friction for radii less than the knee. Again, I have no proof of my theory, nor have I conducted any experiments to prove/disprove it."

Fred W

Design of Railway Location by Clemen C. Williams published in 1924 says this, in part, about this subject.

"Where curves occur on the ruling gradient, or on grades nearly equal to the ruling gradient, the rate of grade must be reduced in order to permit the locomotive to pull its train with no more resistance than it encounters on a tangent on the same grade..."

The book cites American Railway Engineering Association rules which call for compensating curves by between .03 and .05 percent for each degree of curve. Several factors, including the relationship of the train and curve length affect the choice of compensating factor.

Adjusting degree of curve to HO-scale radius, an 18-inch HO-curve is equal to a 45-degree prototype degree curve and a 33-inch curve is equal to a 24-degree curve. So, an 18-inch curve should be compensated by reducing the grade by from 1.35% to 2.25%, and a 33-inch curve should be compensated by reducing the grade by from 0.72% and 1.2%.

Oddly to me, John Allen's adjustment factors of 2% and 0.95% for these two curvatures are comfortably within the range of the early twentieth-century AREA rules.

Nevertheless, I think these factors for HO are something like twice what is necessary. This subject would be a great magazine article for an author who had facilities where the effect of curvature on train resistance could be tested on models.