Parts Sauce

Dear Rick,

Following on from earlier, you've prompted me to go hunting for "Arduino Starter Kit" options.

As a lead-in, I've tried to select the cheapest options I could find that were shipping from within Continental USA,

as current shipping delays and issues are some of the most effective "project momentum/motivation killers" I've seem in quite a while.

It should also be noted that it is always possible to find "a deal" somewhere, if you search the right-thing-at-the-right-time, are willing to be flexible with where the product is actually shipping from, or just "happen to get lucky". In the "electronics experimenters space", there is always subtle changes and evolutions in components and parts,

so expecting to buy "exactly the same thing" even weeks-apart is a fool's errand. Learning the Rules (basics of electronics) so you can known how and when it's permissible to "bend the rules" is key.

So, where do we start?

- You could search-for (and find) umpteen options for "Arduino starter kits", which include a representative set oif components. Kits such as this from eBay.com

https://www.ebay.com/itm/324107849059

(USD$36 + shipping)

will get you

* an Arduino UNO board + USB cable

(IE the barest minimum required to "load a sketch into an Arduino)

* a selection of jumper cables to wire things together "on the workbench"

* a couple of "pluggable breadboard" units to lay out components/buttons/LEDs

* a bunch of resistors, switches, LEDs, and a Servo

(IE the main "Input/Output devices" a model RRer is interested in working with)

and some other assorted interesting doohickys which might become useful to play-with once you're comfy with the "basics of Arduino" and want to extend your repetoire...

(EG Normal and Stepper motors, LCD displays, Ultrasonic and Temp sensors, buzzers, relays, etc)

- HOWEVER, if you're focussed on Dr Geoff's projects to lead your first steps, one key component you'll note is missing is a "Sensor Board".

"Why is this important? I mean, Prof, your own pics above don't show one..."

Well, while the pics above help reconcile the "which pin is which" against the fundamentals of Dr Geoff's example sketches (see the Dec 2016 article), connecting much more than ONE switch and ONE Servo DIRECTLY to an Arduino UNO may start pushing the power-supply limits of the Arduino itself.

By using the Arduino's "5VDC" and "GND" pins, you're loading down the Arduino's onboard power-supply circuitry with the "load" of the Arduino itself _and_ the additional circuitry. Add too much "additional circuitry", and things start not-acting the way you expect.

A Sensor board uses a larger, beefier PSU to provide seperate 5VDC and GND lines to power the "external stuff" (the LEDs and Servos), and leaves the Arduino's onboard power-supply circuitry to just worry about powerng, well, just the Arduino. This gives both "all the power you need, where you need it", AND allows the Arduino to behave in a more "stable" manner.

Look carefully at the example "YFRobot Sensor Shield" below, and you'll notice:

- The BLACK pin headers along the TOP and BOTTOM edges,

which match the UNO Pin positions/numbers in the images posted earlier

(zoom in and check the WHITE labelling of each pin)

- You'll also notice that accross the INSIDE of the PCB is a load of 3-pin-grouped connections.

These BLACK + RED + WHITE groups have "pin labels" which, looky here, seemingly match the "pin numbers" of the UNO pins along the TOP and BOTTOM edges.

EG At BOTTOM RIGHT you can see the "ANALOG IN - A0 / A1 / A2 / A3 / A4 / A5" BLACK pin header

and just above it you can see the matching BLACK / RED / WHITE "A0 / A1 / A2 / A3 / A4 / A5" set of pins.

Follow around the board, and I'm sure you'll identify the other "pin <> pin matches"...

Hopefully it will have also dawned from the previous Arduino pics,

plus Dr Geoff's article,

plus the above pic,

that the "5VDC" and "GND" pins are required to be connected all over the place,

and yet the actual host Arduino only has a few of each connection available at best...

(This is why I put the horizontal groups of 5VDC and GND connections on my "Pro Mini DIY Breadboard" posted earlier...)

The Sensor board provides a dedicated physical 5VDC and GND connection for each of the Arduino pins it "breaks out", making connecting diagrams such as the "LED + Switch" part of Dr Geoff's "6 switched Servos" project a lot simpler. (Each "LED + Button" set needs a 5VDC + Signal-Pin + GND set of 3-connections, and the Sensor board provides all 3 pins for you, right there...  ).

).

"...hold up a sec Prof, how does this Sensor board connect to the Arduino? Do I have to wire a load of jumper wires between them?"

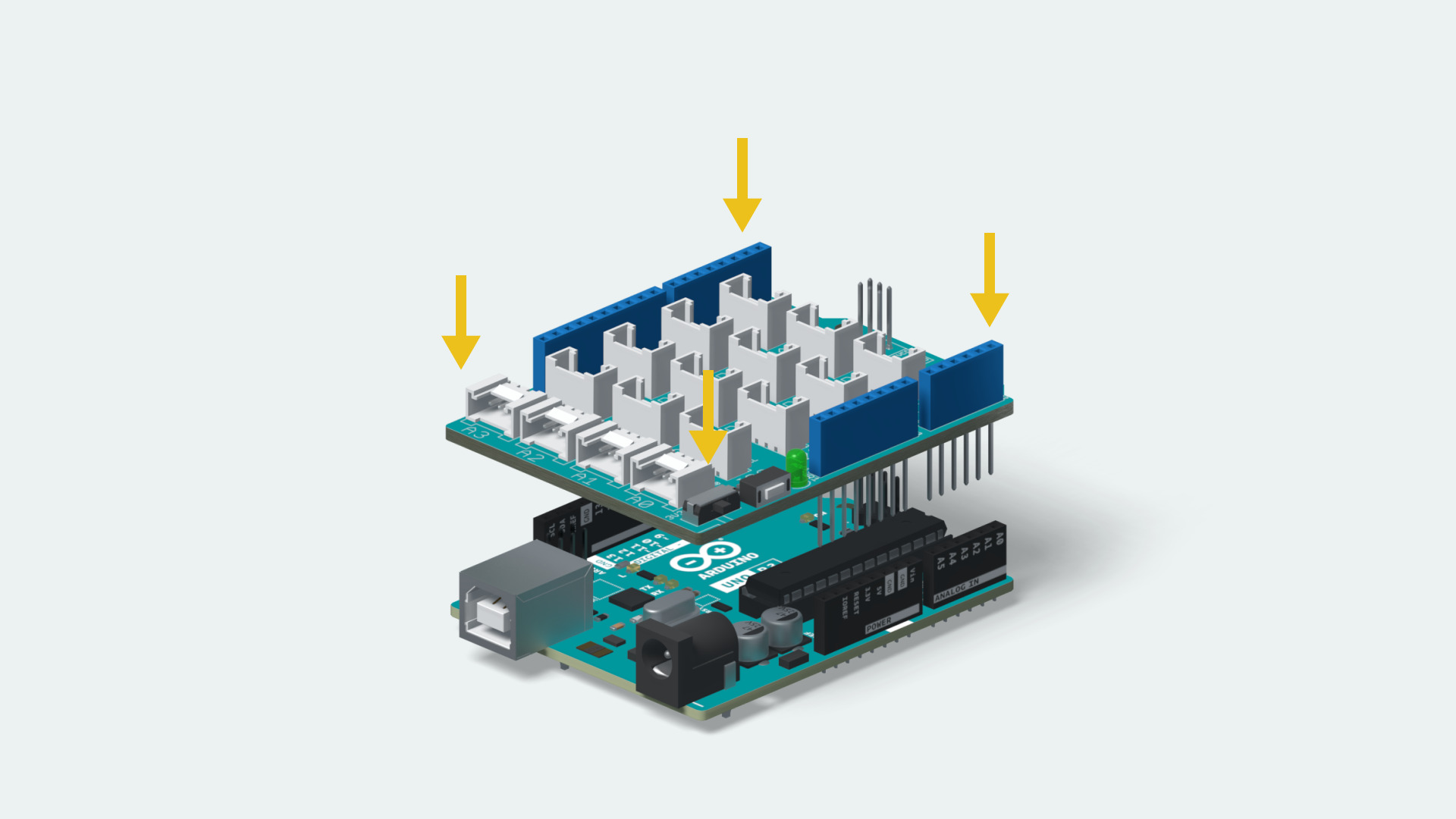

Um, no. The beauty of the physical Arduino "Form Factor" is that "shields", the terminology-name for bolt-on boards such as the Sensor board, simply plug into the Arduino Uno as shown below...

"...sooooo, we've come a Long Way from 'where do I buy stuff'....

what does it mean in $$$ terms?"

Well, as we started this post with, the prefab "All you need Arduino Start Kits" have a lot of useful stuff,

but without a Sensor Board, following along "pin for pin" with Dr Geoff's excellent examples might pose some challenges, like

"how do I get enough 5VDC and GND pins to connect everything up?"

and

"yep, it's all wired up right, but the Arduino is acting flaky with all the extra circuitry hanging off it's onboard PSU circuitry"

SOOOO, the other-end of the spectrum is to purchase "only the bits you need" seperately. IE

- An Arduino UNO

https://www.ebay.com/itm/254928538105

/> (USD$6.70 + shipping)

- a Sensor Shield

https://www.ebay.com/itm/383719978047

/> (USD$6 + shipping)

- an SG90 or MG90 Servo

https://www.ebay.com/itm/283522010547

/> (USD$4.45 + shipping)

- a "grab bag" of buttons/LEDs/resistors

https://www.amazon.com/LAFVIN-Electronics-Component-resistors-Potentiometer/dp/B077QPVXK9

/> (USD$6.50 + shipping)

- and some patching-wires

https://www.ebay.com/itm/253824729484

/> (Make sure to choose "Type = 'All 3'" Less than USD$8.00 + shipping)

(Total of approx USD$32 + shipping)

...and, of course, if you wish to spend a little time with eBay, Amazon, adafruit, SparkFun ,

you may well be able to snag some better prices "in the moment"...

Anywho, that should be enough to set you off and hunting for the moment...

Happy Modelling,

Aim to Improve,

Prof Klyzlr