I had a N Scale layout I've been working on for years, it is gone. But the time came to reconfigure the space and have gone from a rolling table design to an around the wall design.

So now back to the "Dream and Design" stage.

The layout room (an alcove off the rec-room) is 76" x 110" with an option to include a 60" x 12" (maybe upto 14") 'shadow box' in the adjoining rec-room on top of the half wall between the two rooms. I also can 'tunnel" through one of the walls into my workshop so there are options for a staging yard and/or helix out of sight in the other room. But probably not going there.

I've been playing around with multiple options on SCARM and XtrackCAD.

A sample of my 'dreaming' - my more K.I.S.S. design

I have a few big design questions to answer for myself first.

To go to Helix or not to Helix - that is the question

Do I want to go multi-levels - as in two shelves using a helix to climb the 10-12" I would need to gain.

Given my 76" wide alcove I need to go with a narrower radius helix. I have figured out I could do one up to about 14" which can mean a 2% grade. (I have toyed with idea of helix in the workshop room through the wall - a sub-optimal solution I think)

Upside of two levels is obviously more room - but the helix takes up a lot of surface area. A 30" diameter helix takes up 6.25 square feet. Assuming a 14" shelf I would have about 17 Sq feet of upper level space. So have to decide if the space, cost and effort of the helix is worth that gain of about 11 Sq feet of shelf space. Granted the 6.25 sq feet is a 30" square of property while the 11 Sq feet is 176 linear inches 14" wide which offers more MRR options.

So big question one is go with a Helix to two levels or not?

What say ye MRR Enthusiasts, is a Helix worth it in this layout room?

I below is one way I might go to Helix

few of my 'given's and druthers"

- I'm using Code 55 Peco track and Code 80 Peco switches (yes apparently they are compatible) I have about 40 of the peco Code 80 switches so switching my switches isn't an easy option.

- I'd like to keep my main line to a 14"R and maybe 10" on yards and tight spaces like the dock area.

- I want a absolute minimum of 22" aisle width at pinch point - wider in 'work area'. I play alone - maybe a guest once in a blue moon. Designed for solo operations

- Reach is kept to about 26" (yes I need to stretch to do that). less is better

- Climb to be limited to 2%. In the helix if double tracked the down track can exceed 2%.

- Maybe a duck-under bridge (that is hinged or lift off too)

- Planning on two track main, with one completely isolated independant line for DC and then the rest in DCC. So I can run some of my non-converted old engines.

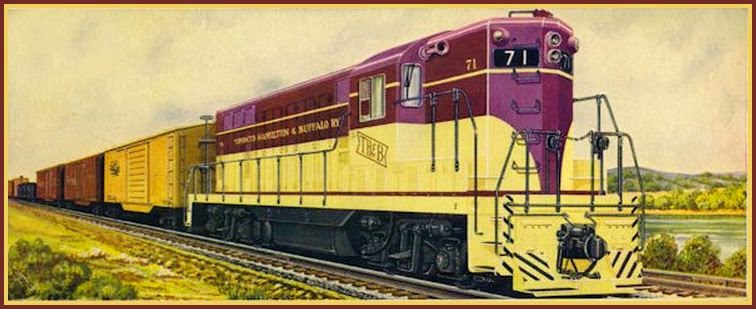

- I tend to run small transition era diesels but do have several vintage steamers. I have some passenger cars that I do run so the wider the radius the better.

- My priority is realistic scenery, rather detail a building than solder electronics. But do have a fine Weller solder station and do that, just more of an 'artist' than a technician.

- I have young grand kids - so kid proofing matters. (so far do not have any Thomas cars).

- I want a

- townsite (with trolley line),

- dockside complete with car float dock,

- a small yard,

- a couple of industries,

- space for a fun amusement park (have several rides models to assemble)

- and a campgrounds.

David

aka Fort Kent Dad or FKD for shortAlberta, Canada