Note: I plan on adding more pictures and details to this entry as I find them on my computer.

In 2009, while railfanning along Norfolk Southern’s Port Road line in Lancaster, PA, I came across a

continuous welded rail train parked on a siding. At the time, I thought to myself “This would make a

really interesting model if I could figure out how to do it someday”. I took quite a few pictures of the

subject, and stashed them away for later use. The prototype was still wearing Norfolk and Western

reporting marks. All of these cars on my prototype were based on a 53” GSC flat car. I have also seen

these trains with old 40’ riveted body flat cars as well. At the head end of the train, there is usually

a “threader” car that helps get the rail onto and off of the ROW and into the guide chutes. After the

threader car comes a guide car. This car has a set of movable guide chutes and a set of fixed guide

chutes. These chutes help direct the rail into the next car, the “power car” or sometimes called a

“puller”. This machine helps pull the 1/4-mile long segments of rail onto and off of the rail storage cars.

After the puller car, another guide car helps direct the rail into the storage racks on the train. Both guide

cars are identical copies of each other, with the fixed guide chutes oriented closest to the puller car.

After doing some research, I learned that these specialized pieces of equipment were built by a single

manufacturer and sold to several railroads over the years. Some have been modernized and retrofitted

with some newer machinery, but the basic puller and threader cars are all fairly similar. The greatest

area of variety lies in the rack cars that store the long lengths of rail. Some railroads have racks that

store 3-4 shelves worth of rail. Others, like my prototype, have upwards of 9 levels to them.

Fast forward to a few short years later to 2012. I had recently began to learn the craft of

solid modeling on the computer as a new part of my job. Around the same time, I was tasked with

learning the ins and outs of our new 3D printer we purchased for producing prototype parts. 3D

printing has rapidly grown in the last few years, and the possibilities of their use seem to be limitless.

At the time, producing entire HO scale models was not a possibility due to cost and lack of fine detail.

However, a light bulb went off in my head- what if I use this technology to replace some of the difficult

scratchbuilding tasks in my modeling? Then I remembered that rail train…a perfect candidate for

exploring 3D printing.

After some experimentation, I decided that a mix of scratchbuilding, kitbashing and 3D printing

could really change the way I approach my modeling projects. Through trial and error, I learned what I

could and could not print effectively. Thankfully, the modeler now has many more resources available

to them to help them learn how to design 3D printed parts. Shapeways.com has a guide that helps

illustrate how thin walls and posts can be in order to maintain their shape and minimize warpage of the

part during and after printing. Once you are familiar with these guidelines, you will be able to effectively

design parts for your own use.

Modeling:

I decided that since my prototype was based on a 53’ GSC flat car, I would use the old Walthers

3 in 1 GSC flat car kits. These have become hard to find lately, so I also used the Tichy #1000 53’6” GSC

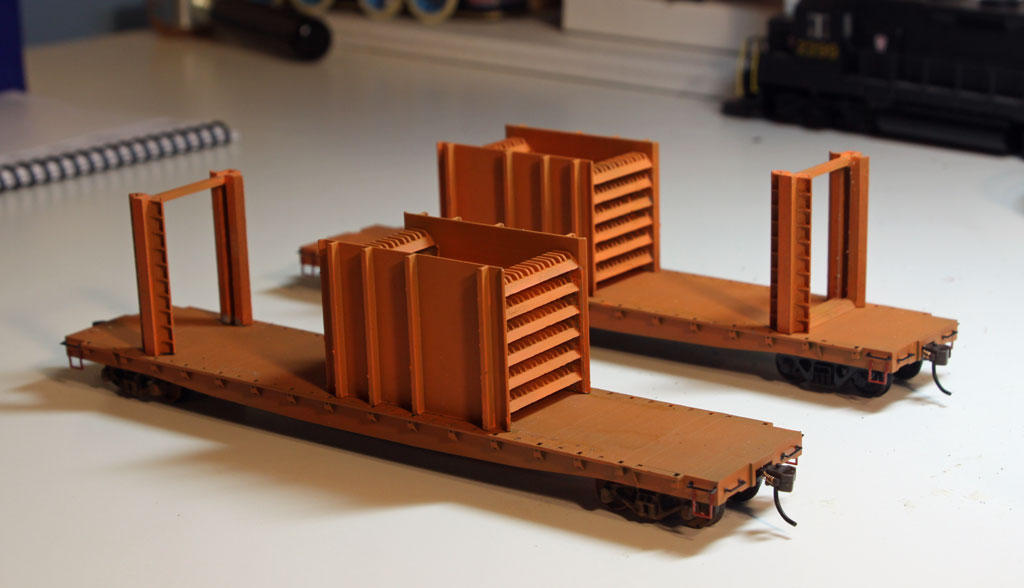

flat car kits. The easiest and most plentiful car that needs to be modeled is the storage rack car. A typical

train has about 30 of these cars in the consist. I chose to model 16 of them for my own train. Scratch

building them out of styrene seemed like a daunting task, and this would cause a lot of modelers to not

even consider taking this project on. The racks themselves are rather complex to model accurately, so I

decided to draw a scale model of these racks using Solid modeling software. Using the design

constraints listed on the Shapeways website, I was able to develop a convincing rack model for my

storage cars. When I was happy with the model on the computer, I saved the file as a .STL file, and

uploaded it to the Shapeways site. The nice thing about Shapeways is that you can set up a storefront

easily and allow the public to purchase your models. All of my 3D printed models in this series are

available to purchase through the Shapeways site.

Once the parts arrived, they will need to be cleaned thoroughly to remove any residual support

wax left over from the printing process. This is very important; you will have trouble getting paint to

adhere to the parts if this was has not been removed. I added .010” styrene strip and .080” channels

onto the printed parts with CA adhesive. I prefer the Gorilla brand CA when working with 3D printed

parts, because it is supposed to have some flexibility to the cured glue that the other brands do not

have. I drilled and glued a couple of brass wire posts to the bottom of the rack to make the connection

between the rack and the flat car stronger. Once dry, I added the final support braces to the sides of the

rack. These support braces would have been too thin to print out on the original printed part. Once the

support braces have been glued in place, I painted the entire car a light primer grey color. Once dry, I

finished up with a top coat of MOW orange paint.

Car #1- this car guides the rail onto the railbed. I cut town a Tichy flat to make it narrower, like the prototype.

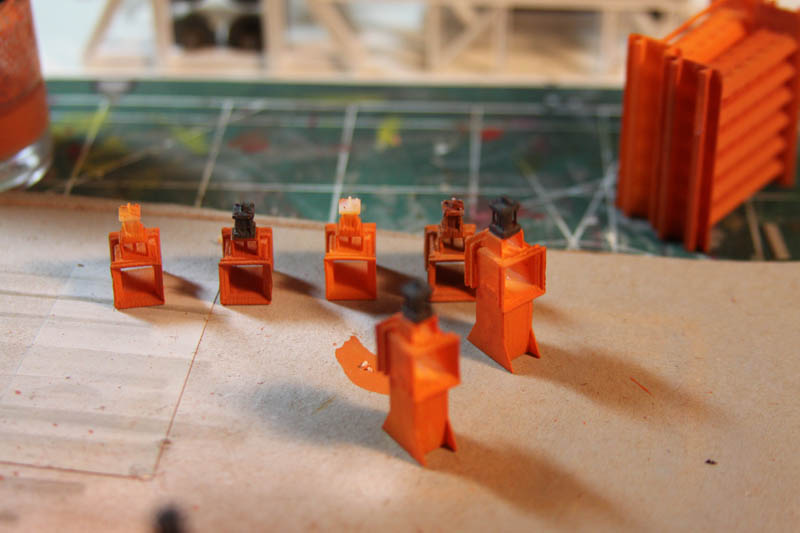

Second car- Fixed and adjustable guide chutes. Tichy kit with printed chutes and also the fixed chute stands are printed.

3D Printed guide chutes:

Car number 3- Puller unit...this is all scratchbuilt, no printed parts.

Car 4- second car with fixed/adjustable chutes:

Again, plastruct shapes and printed guide chutes.

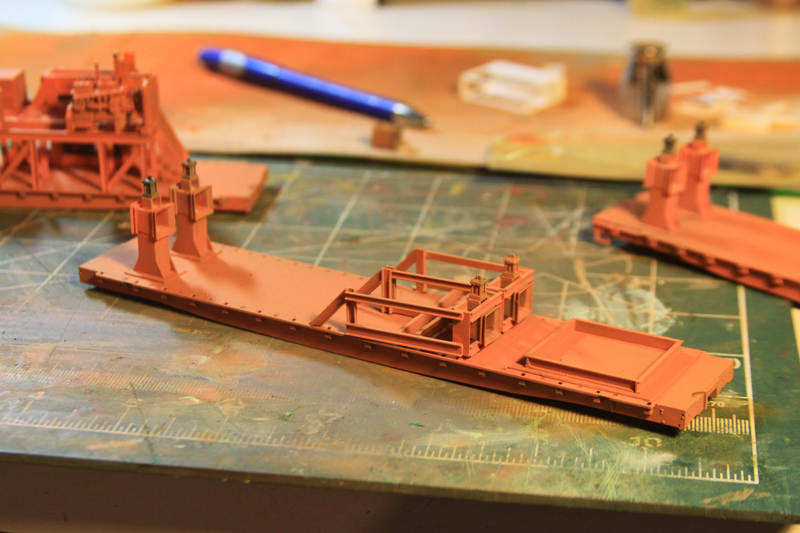

Car 5- The beginning of the rail guide car:

Rail rack cars (5-15 units):

Natural finish of the 3D printed part:

Middle anchor car (not built):

Then there are 5-15 more rack cars, followed by another end rack car.

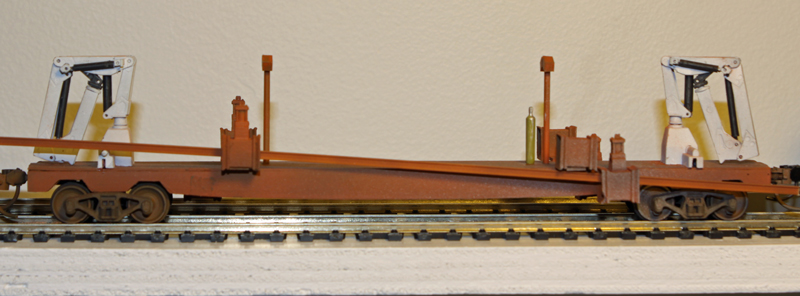

Entire threader assembly lined up:

Youtube videos of the train in action:

.