Plan B: Logic

I needed a better plan, and some sort of verification that I was on the right track with the drawings I'd already done. Logic to the rescue!

I know the capacities of the 5 tenders in question. #s 20&21 had 4500 gallon tanks, while #s 22-24 had 5000 gallon tanks. I also felt safe in assuming that there were at most three tender designs. #s 20&21 were siblings, built at the same time by the same builder, though one was a 4-6-0, the other a 2-8-0. The builder's photos of both definitely seem to show identical tenders, right down to the number of rivets (yes, I counted them). #s 22&23 were twin sisters, so logically they had the same tenders. #24 was built a little later, and by a different builder, but the tender having the same capacity made me think that it would be similar if not identical. The rivet patterns bore this out - similar, but not identical. The overall size certainly seems to be the same, or at least very close.

So far so good. I'm working under the assumption that there are two basic designs, with one of the larger tenders having the same size but a different internal structure and therefore different a rivet pattern - easy to deal with using rivet decals. So it looks like two frames and two tanks will need to be designed, which is a significant improvement from the original 4 different designs. But is that it?

Southern Railway had a major influence on the D&W. The locomotives seem to have used standard Southern cabs. The Baldwin orders repeatedly refer to "Sou. Ry. Std." for a number of minor details. And it just so happens that I have quite a few drawings of Southern steam locomotives. I wonder if any of them might have had similar tenders? I went looking for tenders of similar age and capacity, and lo and behold, I found some.

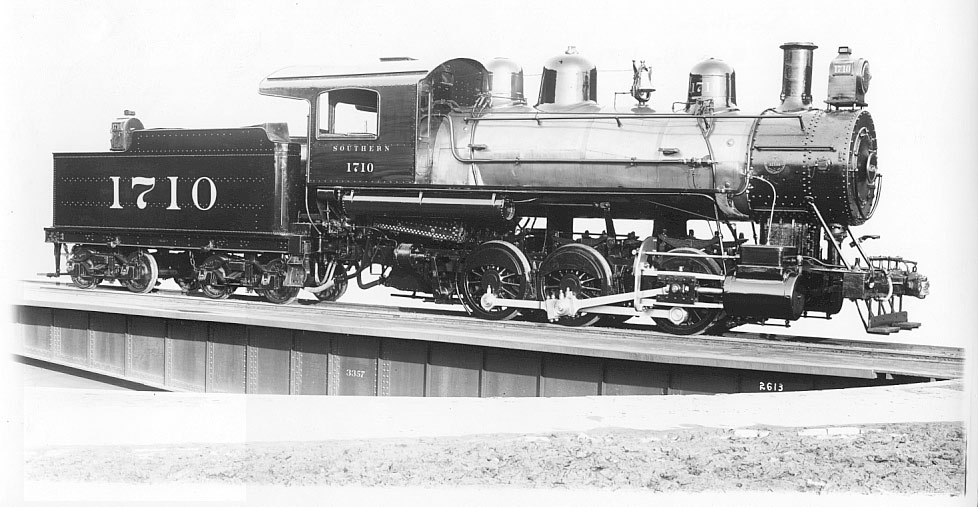

The 4500 gallon tender I found behind an 0-6-0 switcher. Other than a different coal bunker and the lack of a vertical seam on the tank, it looks like a dead ringer. I even found what looks like a Baldwin builder's photo that looks almost exactly like the builder's photos of #s 20&21:

And, I even have some really good drawings of that engine, thanks to an article in the March '91 Mainline Modeler, of which I have an electronic copy. Fixing the coal bunker to suit my needs will be child's play, with accurate drawings of the frame in hand.

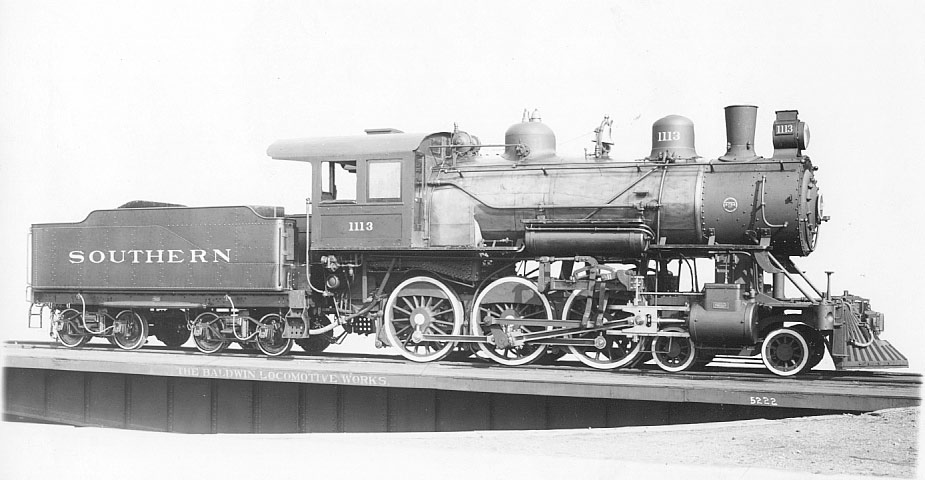

One down, one to go. I managed to find a few Southern engines with 5000 gallon tenders as well. Most of them were older, which didn't really help me much. All of them had the older style horseshoe tanks, whereas my engines had the newer style tanks with the coal bunker coming all the way to the outside, and smaller water legs up front. But there in the list of locomotives from 1929, was a reference to an engine built after 1900 with a 5000 gallon tender. And when I looked for it, I found this:

Eureka! The rivets match perfectly, the bunker has the same shape. I'd be willing to bet that the tender behind #24 was a dead ringer for the one above. And, while I don't have plans for that engine, I do at least have an elevation drawing which shows the bolster spacing and (most helpfully) tank length and width. I'll have to extrapolate the frame dimensions, but that looks doable.

So now I have drawings. The 4500 gallon tender will have a 12' bolster spacing, while the 5000 gallon tender will have a 12' 9" spacing. The larger tank is about a foot longer and an inch wider. Comparing the drawings of each tender, it looks like I can simply stretch the smaller one by 9" to get the larger one. If that's not exactly what was done, it would certainly be within a few inches anyway, so that's what I'll do.

So now there's a critical question. How does my Sketchup drawing (made without any dimensional information about the tenders) compare with my deductions based on Southern and Baldwin practice? Well, I was off. Way off. But when I scaled my drawing down about 10%, it turns out that I was within a couple inches all around. That's good enough for me. It makes me think that at the very least my logic is not completely off, and that building tenders from the plans as described will yield reasonably accurate models.

Not bad for starting with a handful of photos and no drawings, huh? Time to get started!